Arb Twin Compressor Wiring Diagrams are essential tools for anyone working on electrical systems in vehicles. These diagrams provide detailed information on how the components of the compressor are connected and how they function together to ensure proper operation. Understanding how to read and interpret these diagrams is crucial for troubleshooting electrical issues and ensuring the compressor operates efficiently.

Why Arb Twin Compressor Wiring Diagrams are Essential

Arb Twin Compressor Wiring Diagrams are essential for several reasons:

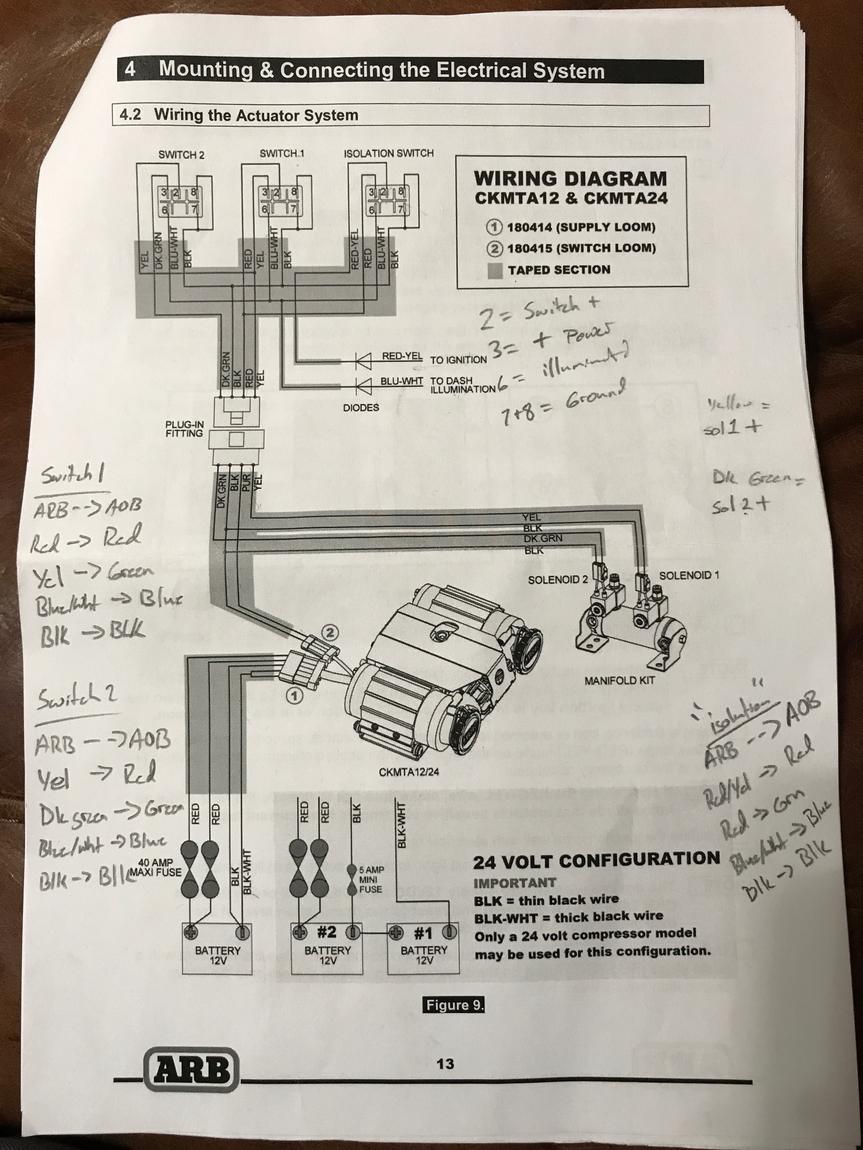

- They provide a visual representation of how the compressor’s components are connected.

- They help in understanding the electrical system of the compressor.

- They aid in troubleshooting electrical problems efficiently.

- They ensure proper installation and maintenance of the compressor.

Reading and Interpreting Arb Twin Compressor Wiring Diagrams

Reading and interpreting Arb Twin Compressor Wiring Diagrams can be daunting for those unfamiliar with electrical systems. Here are some tips on how to effectively read these diagrams:

- Start by identifying the components of the compressor on the diagram.

- Follow the lines connecting the components to understand how they are connected.

- Pay attention to symbols and color codes used in the diagram to decipher the connections.

- Refer to the legend or key provided with the diagram for additional information.

Using Arb Twin Compressor Wiring Diagrams for Troubleshooting

Arb Twin Compressor Wiring Diagrams are invaluable for troubleshooting electrical problems in the compressor. Here’s how you can use these diagrams effectively:

- Identify the problem area on the diagram based on the symptoms observed.

- Trace the wiring to locate any loose connections or damaged components.

- Refer to the diagram to understand the flow of electricity and pinpoint the source of the issue.

- Use a multimeter to test the continuity of the wires and components as per the diagram.

When working with electrical systems and using Arb Twin Compressor Wiring Diagrams, safety should always be a top priority. Here are some safety tips and best practices to keep in mind:

- Always disconnect the power source before working on the compressor.

- Use insulated tools to prevent electrical shocks.

- Avoid working in wet or damp conditions to prevent short circuits.

- Double-check all connections before powering up the compressor to avoid damage.

Arb Twin Compressor Wiring Diagram

Arb Twin Air Compressor Wiring Diagram System – Orla Wiring

ARB Dual Compressor Simple Wiring – YouTube

Arb Compressor Switch Wiring

Arb Compressor Wiring Diagram

Arb Twin Compressor Wiring Diagram » Wiring Draw And Schematic

Arb Compressor Switch Wiring Diagram – Diariesid