When it comes to aircraft maintenance and troubleshooting electrical issues, understanding the Plane Power Alternator Wiring Diagram is crucial. These diagrams provide a detailed visual representation of the electrical system in the aircraft, helping mechanics identify and resolve any wiring problems efficiently.

Why are Plane Power Alternator Wiring Diagrams essential?

- Helps in understanding the electrical system layout

- Aids in identifying wire connections and components

- Facilitates troubleshooting electrical issues

- Ensures proper installation and maintenance of the alternator

How to read and interpret Plane Power Alternator Wiring Diagrams effectively

Reading and interpreting Plane Power Alternator Wiring Diagrams may seem daunting at first, but with some guidance, it becomes much more manageable. Here are some tips to help you make the most of these diagrams:

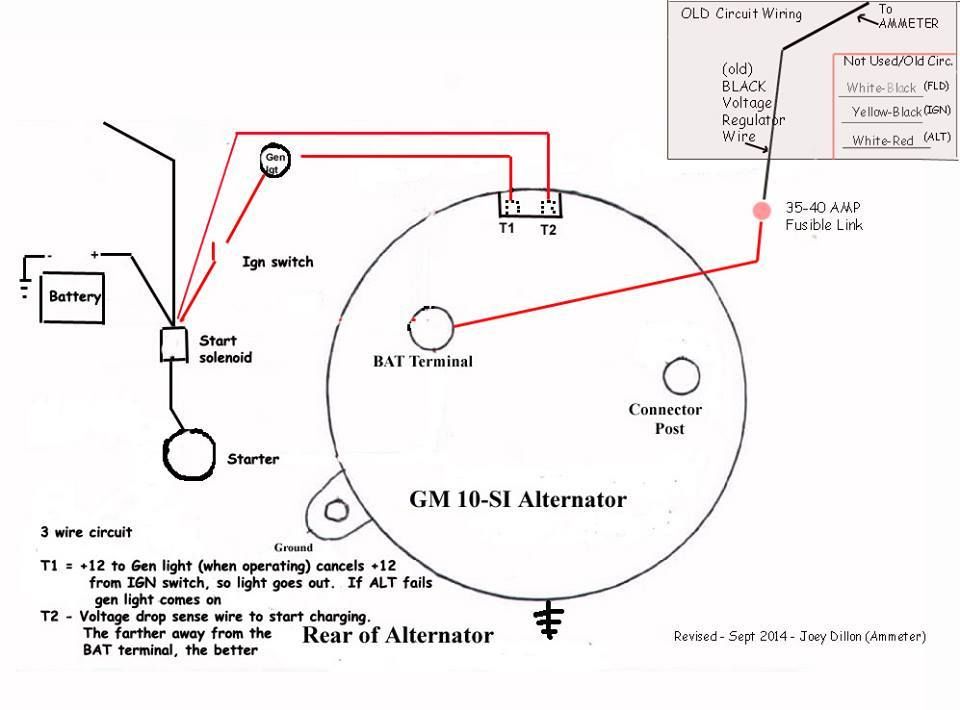

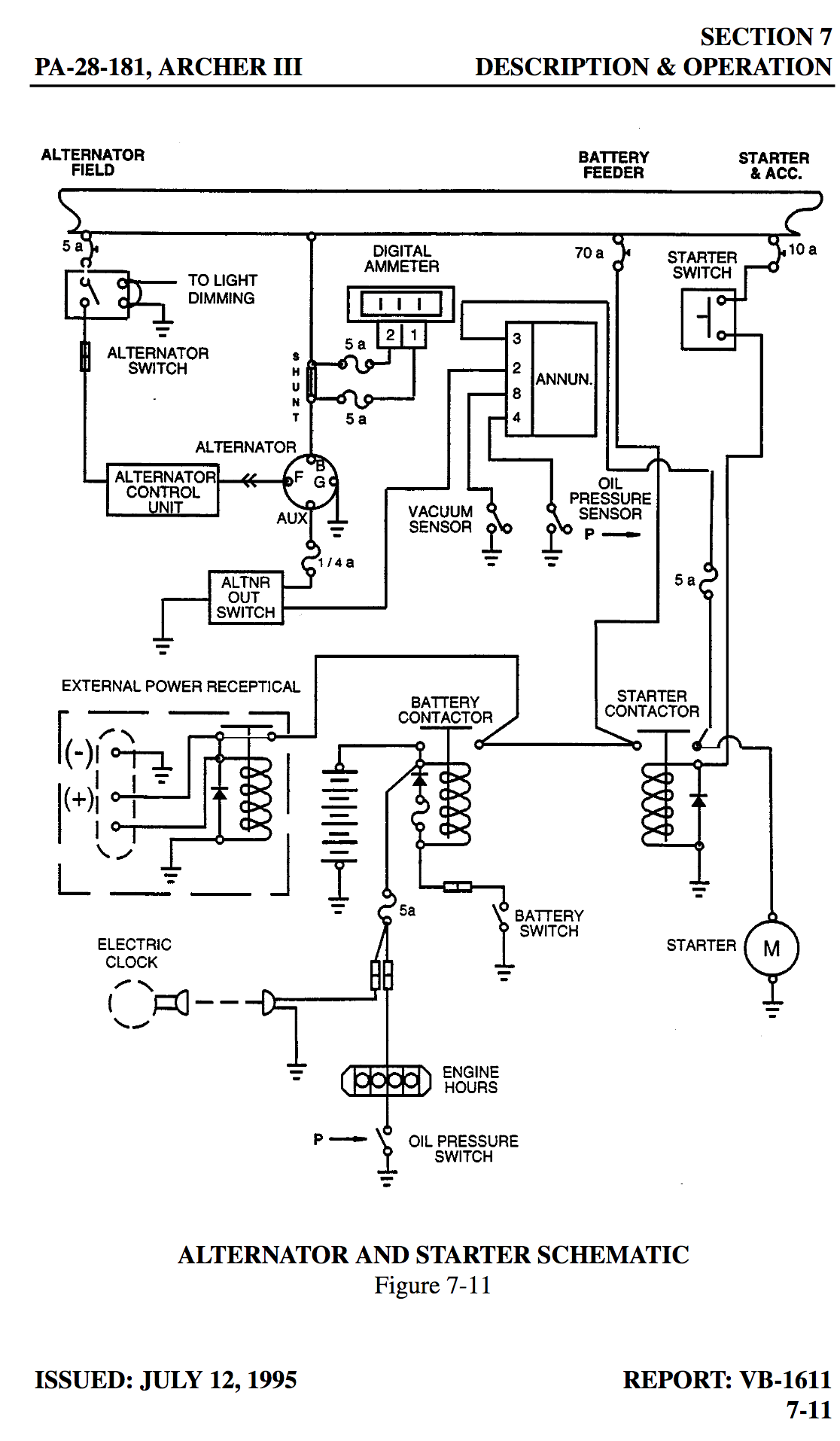

- Start by familiarizing yourself with the legend or key provided on the diagram

- Identify the different components, wires, and connections in the diagram

- Follow the flow of electricity from the alternator through the various components

- Pay attention to color codes and symbols used in the diagram

Using Plane Power Alternator Wiring Diagrams for troubleshooting electrical problems

When faced with electrical issues in an aircraft, the Plane Power Alternator Wiring Diagram can be a valuable tool in identifying and resolving the problem. Here’s how you can use these diagrams effectively for troubleshooting:

- Trace the wiring from the alternator to the affected component to pinpoint the issue

- Check for loose connections, damaged wires, or faulty components indicated in the diagram

- Refer to the diagram to ensure proper reconnection of wires after repairs

- Use a multimeter to test the continuity and voltage at various points in the circuit

Importance of safety when working with electrical systems

Working with electrical systems, including Plane Power Alternator Wiring Diagrams, requires a keen focus on safety to prevent accidents and injuries. Here are some safety tips and best practices to keep in mind:

- Always disconnect the power source before working on any electrical component

- Wear appropriate protective gear, such as gloves and safety goggles, when handling electrical systems

- Avoid working on electrical systems in wet or damp conditions

- Double-check your work and ensure all connections are secure before re-energizing the system

Plane Power Alternator Wiring Diagram

Plane Power Alternator Wiring Diagram Sample | Wiring Diagram Sample

All You Need to Know About Plane Power Alternator Wiring: A

Plane Power Generator To Alternator Kits | Pilotshop.com

Welcome to JT's RV8 Aircraft Factory!: Alternator all Wired Up!

Wiring Diagram How An Alternator Works – Wiring Diagram

Technical – alternator wiring? | The H.A.M.B.