Are you looking to understand how Schematic Fog Machine Remote Wiring Diagram can help you troubleshoot electrical problems effectively? These diagrams are essential tools for anyone working with fog machines, as they provide a visual representation of the wiring connections and components involved in the system.

Why are Schematic Fog Machine Remote Wiring Diagram Essential?

Schematic Fog Machine Remote Wiring Diagram are essential for the following reasons:

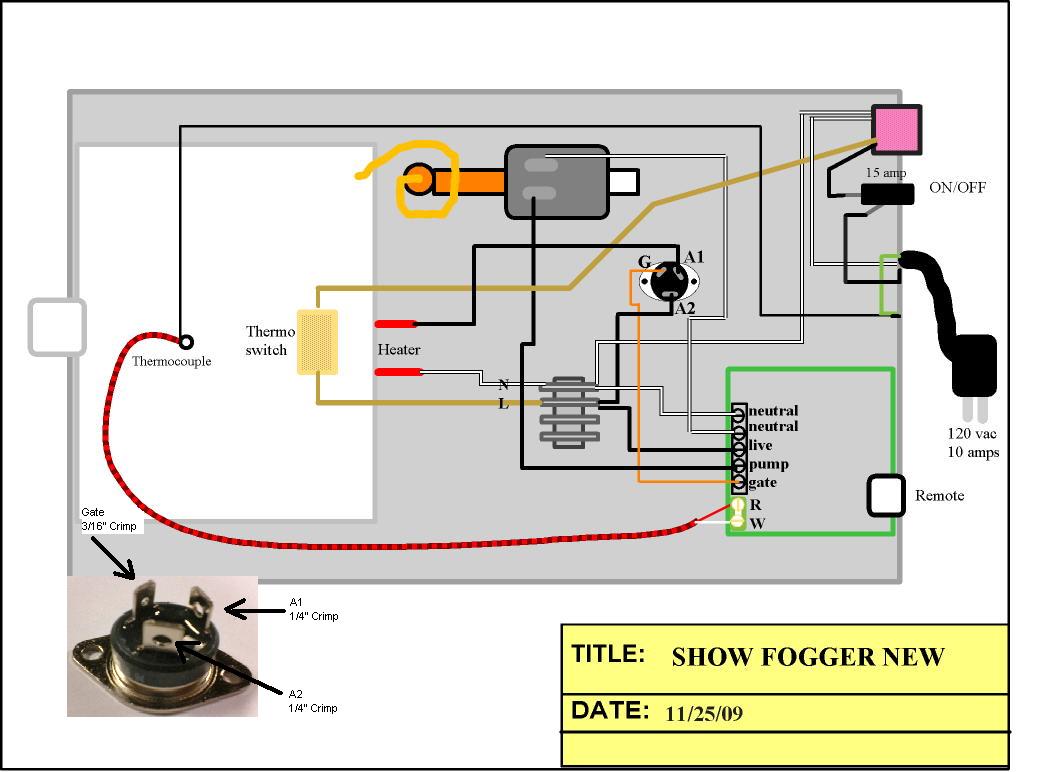

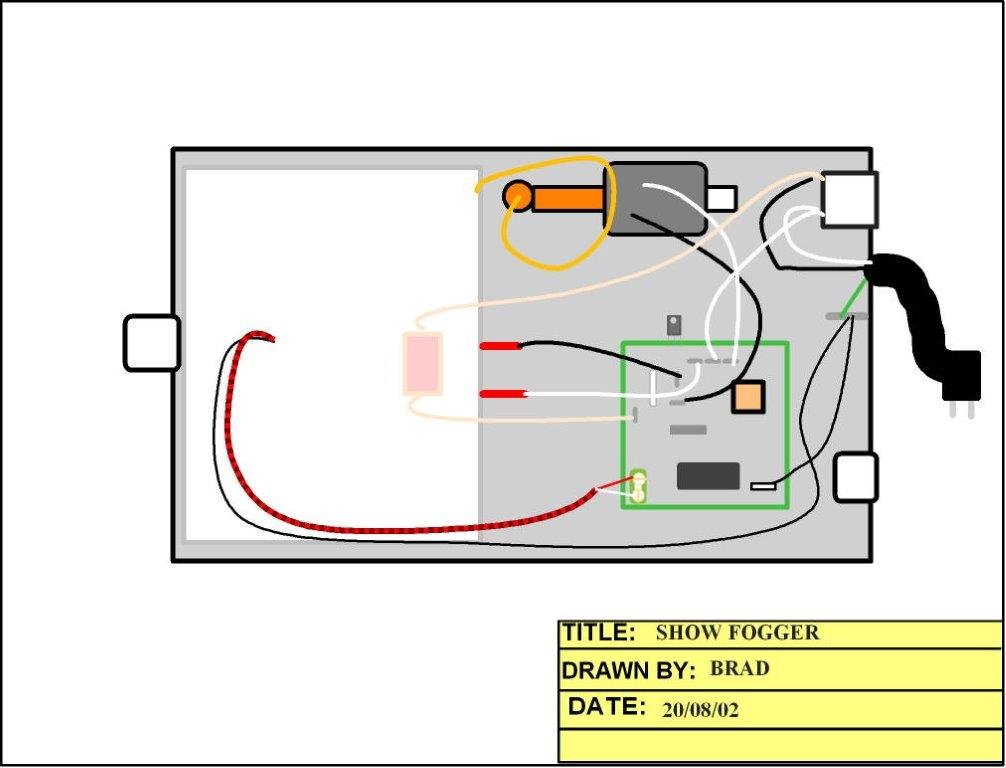

- They provide a clear visual representation of the electrical connections within the fog machine system.

- They help users identify the different components and understand how they are interconnected.

- They assist in troubleshooting electrical issues and ensuring proper installation and maintenance.

How to Read and Interpret Schematic Fog Machine Remote Wiring Diagram

To effectively read and interpret Schematic Fog Machine Remote Wiring Diagram, follow these guidelines:

- Start by identifying the key components of the fog machine system, such as the remote control, power supply, and fogging unit.

- Follow the lines and symbols on the diagram to understand how the components are connected and the flow of electricity through the system.

- Refer to the legend or key provided on the diagram to understand the meaning of different symbols and colors used.

Using Schematic Fog Machine Remote Wiring Diagram for Troubleshooting

Schematic Fog Machine Remote Wiring Diagram can be used effectively for troubleshooting electrical problems by:

- Identifying potential issues such as loose connections, short circuits, or faulty components.

- Following the wiring diagram to trace the flow of electricity and pinpoint the source of the problem.

- Using a multimeter to test the continuity and voltage at different points in the system as indicated on the diagram.

Safety Tips for Working with Electrical Systems

When working with electrical systems and using wiring diagrams, it is crucial to prioritize safety. Follow these safety tips and best practices:

- Always turn off the power supply before working on any electrical components.

- Use insulated tools and wear appropriate personal protective equipment, such as gloves and safety goggles.

- Avoid working alone and ensure someone is nearby in case of emergencies.

- Refer to the manufacturer’s instructions and guidelines for proper installation and maintenance procedures.

Schematic Fog Machine Remote Wiring Diagram

Simplified Guide to Wiring a Fog Machine Remote: Schematic Diagram Included

Chauvet Fog Machine Remote Control Wiring Diagram

Chauvet Fog Machine Remote Control Wiring Diagram

Schematic Fog Machine Remote Wiring Diagram

Cosplay Electronics 201: Making a Mini Fog Machine – Valkyrie Studios

Simplified Guide to Wiring a Fog Machine Remote: Schematic Diagram Included